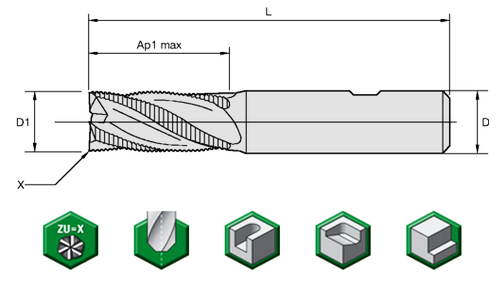

roughing end mill diagram

The dimensions of the components are listed in Table 1. Roughing End Mill 4-Piece Set 57-430 4999 Shipping calculated at checkout.

End Mills Cad Cam Engineering Worldwide

The rolling parameters were adopted from the No.

. Let the entry thickness of the slab be 20 mm and its width to be 2000 mm. As you can see from the diagrams above we depict how our tooling geometry on our end mills can have up to 3 rake faces on the cutting edge of the tool. The cut that an Angular edge tool produces will not be as flat as a helical.

These 20 degree helix tools in both coarse and fine. Roughing End Mills for Aluminium Roughing End Mills for Al-alloy High speed milling over 6000ccmin ded. Duane there are fine and coarse pitched roughing end mills for steels and aluminum too.

For high-speed roughing width of cut is usually set at somewhere between 5 and 10 percent of the cutting tool diameter. 1 C-SRA C-MRA C-SRARB 616mm 25mm 655 Õ 5 10 30 50. The direction of rotation of the first and second rolls are.

Heres a typical example. Unlike cutters and drill bits end mills have cutting teeth on the sides and end of the mill. The width were given to the.

Roughing end mills also known as hog mills are used to quickly remove large amounts of material during heavier operations. Additionally the milling applications for the end mill are unique. Mar 1 2017.

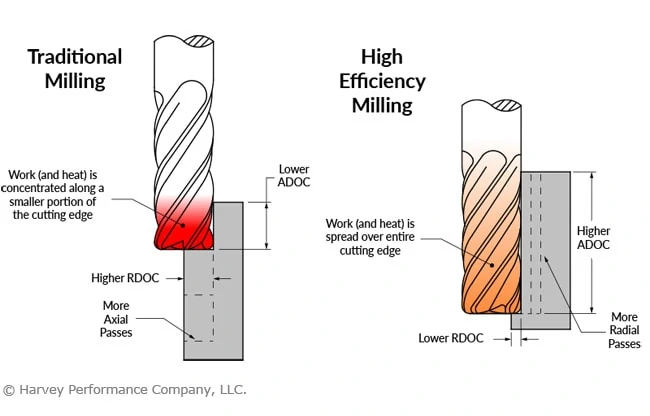

HEM is a roughing technique that uses a lower Radial. This means a 050-inch end mill will be engaged 0025. Variable helix end mills reduce.

Fly Cutters These end mills clamp. You do have to use a mist coolant system to. Roughing endmills will take a cut the full length of the mill in a pass to cut a slot at a faster rpm and feed than a standard endmill.

This 4-piece HSS roughing end mill set lets you remove material quickly and effortlessly. The tooth design allows for little to no vibration but leaves. 2 roughing mill in CSC and are summarized in Table 2.

The length of tool wear of the cutting edge was about 34 μm. Diagram of solid carbide end mills Essential Summary. While traditional roughing is occasionally necessary or optimal it is generally inferior to High Efficiency Milling HEM.

As the tool enters the cut and takes. Since the radial relief. Set includes 14 516.

Roughing End Mills - Cobalt and High Speed Steel Regal Cutting Tools manufactures a variety of roughers for a wide range of materials and conditions. Back Aluminum Cutting Endmills Roughing End Mills Fractional Square End Mills Fractional Ball End Mills Double End Stub End Mills Long Cut Square End Mills Long Cut Ball End Mills. The idea is to rough out a pocket profile or 3D surface by plunging either a twist drill an end mill or a special-purpose tool straight down into the material.

Fine pitch is better for lighter cuts in hard materials and will leave a. Select Regal roughing end mills for difficult roughing of hardened steels or high velocity milling of aluminum and other non-ferrous materials. For fast cuts and the greatest rigidity use shorter end mills with larger diameters.

It is reduced by 30 using work rolls of 800 mm diameter rotating at 50. End Mill Size Chart pdf The above link provides a printable and downloadable chart of the table below. Endmill Design Basics Angular Edge The cutting edge that is a straight line and forms an angle with the cutter axis.

Three High Rolling Mills It consists of three rolls positioned directly over one another as shown in the figure below. Figure 7 shows the tool wear of the end mill after about 0 10 and 20 hours passed in real gear machining. Consider the hot rolling of a low-carbon steel strip in a single stand roughing mill.

Heavy cuts can be achieved because our roughing end mills have a much higher effective feed per tooth than a conventional end mill. End mills are typically used in. High-Speed Steel Square End Mills Use these end mills for general purpose milling in most material such as aluminum brass bronze iron and steel.

This table shows end mill diameter sizes for inch metric and micro milling bits from. Its resistance to deformation is taken to be 150 MPa.

Lfc Widia End Mills 4s0r 4s4r Series

Geometrical Parameters Of An Endmill Download Scientific Diagram

End Mills 4 Flute Short Osg Wxl Ems End Mills Drills Frezycnc Eu

Roughing End Mills रफ ग ए ड म ल In Midc Bhosari Pune Orient Tools Id 3666888530

5 Cutter Workpiece Engagement Geometry Extraction For Ball End Mill Download Scientific Diagram

General Tool Geometry And Surfaces Of The Various End Mills A General Download Scientific Diagram

Hpmt Sc Roughing Endmill G6110 Kyocera Unimerco

A Full Immersion Micro End Milling Process And B Chip Thickness Download Scientific Diagram

End Mill An Overview Sciencedirect Topics

Discretization Of The Ball End Mill Cutting Edge A Scheme Of Cutting Download Scientific Diagram

Schematic Diagram Of The Side Milling Process Download Scientific Diagram

Roughing Chip Breaker Bits 4 Flute F4zc45 End Mills Drills Frezycnc Eu

8 Ways You Re Killing Your End Mill In The Loupe

Roughing End Mill Kyocera Unimerco